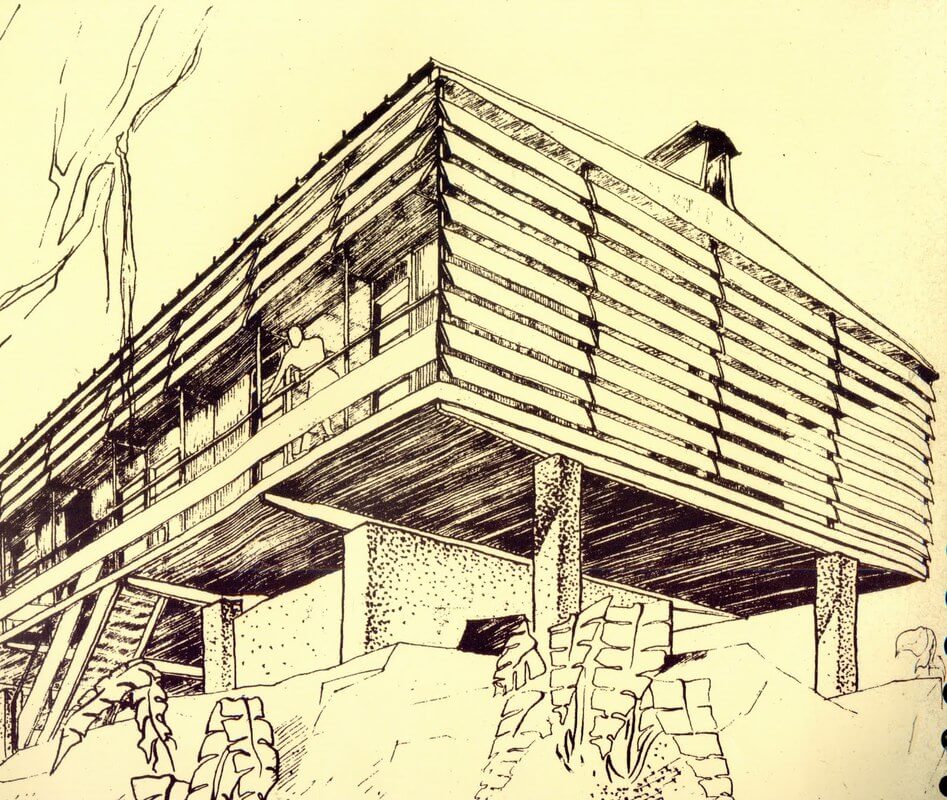

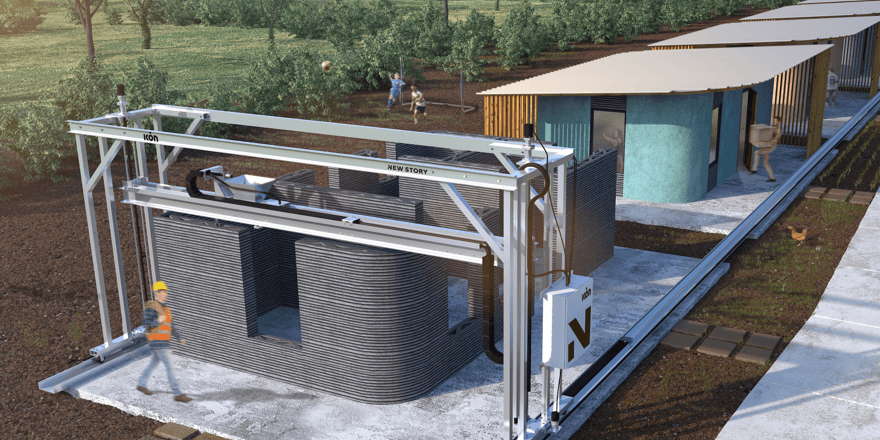

Prefabricated houses have always stood at the forefront of building techniques and housing architecture, marking the evolution of dwelling culture since their very beginning in the heart of the Victorian era. They were flourished in the mid-century all over the world, and in America, were produced by several companies headed by Sears, Roebuck and Company, which sold houses via mail-order catalog, developing a concept of packaging and shipping high-quality pre-cut materials and precise instructions directly to the client. Now, we see the new generation of prefabricated houses, which are 3-D-printed. Unveiled this week at SXSW, an Austin-based startup, the houses on display is made in concrete, and while it does not have the digital aesthetics that we saw, for example in the first 3-D-printed bridge by Joris Laarman, it is highly innovated in its technology. Produced by ICON, it costs only $10,000 to build and can be 3-D-printed by a Vulcan printer in 12 to 24 hour,s using the most common building materials. This model includes a living room, bedroom, bathroom and curved porch and will be the point of departure for an entire project in the developing world. Together with housing nonprofit New Story, it seeks to build a community of 100 homes in El Salvador next year using the Vulcan printer. Above: Julius Shulman Photography Archive, Research Library at the Getty Research Institute (2004.R.10).